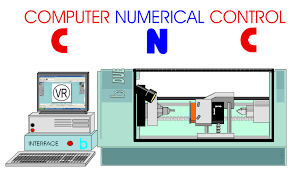

CNC, or computer numerical control, is a way to make machines do the same thing repeatedly. This is used in all kinds of manufacturing processes. You may have already seen CNC routers at your local backspace or Hackspace.

There are many different types of CNC machines. Each has its own advantages for different types of work. This article will give you an overview of CNC milling and how it works. Let’s get started!

What is CNC Machining, and How Does it Work?

CNC, or computer numerical control, is a technology that allows machines to execute the same operation repeatedly. This is used in virtually all forms of manufacturing.

When using a CNC cutting mill, the first step is to create a computer code. This code tells the machine where to move, how fast to cut, what tools are used, and what material it is cutting. The code can be written in different languages depending on the CNC mill.

After the code is complete, the operator puts it into the CNC control system. They then turn on the power to the machine. The next step is to run a test program to make sure everything works correctly.

Once you have verified that everything works as expected, you set up the workpiece in place while it is machined. The machine operator can then provide you with a wood cutting service.

Programming of CNC Machines

There are two ways to control a CNC cutting mill. You can use open/closed-loop machining systems or fully automated systems. Each has its advantages and disadvantages, but they create similar items from roughly the same material. Let’s explore what I mean by those two options.

Open/Closed-Loop Machining Systems

Open/closed- machining is an older way to control CNC machines. This system works by the computer reading where the head is on the x/y-axis and then commanding that axis to move according to your written code. The machine will only move on its axes as commanded by the program.

Open/closed-loop machining systems have two advantages: speed and versatility. They are faster than fully automated methods because they don’t have to run complex programs or processes. However, they are one-directional. They stop when they reach the end of their programmed path.

These machines are not suitable for tasks that involve interruption. For example, if somebody runs into them or needs to do something that is not in order. They are better for tasks like engraving and cutting through more than 1-2 inches thick material.

Automated CNC Machining

This is also called computer numerical control programming language. This means that it uses a step-by-step process to complete each step before moving on to the next task. You will first need to write a “program” in a machine-specific computer language to use this system.

Once this is complete, you will need to repeatedly use the same program or run it from an outside source that gets updated with new code each time you want to make changes.

The main advantage of using fully automated methods of CNC programming is that the machines are very flexible. This means they can handle tasks where the path might frequently change because the operator has to switch out tools or thinks about another task while they are running.

The disadvantage is that these machines are slower because they have to think and plan every step, rather than doing one part at a time like open/closed systems do. They also need special devices attached so that the computer can get information from sensors that tell it how much material has been cut and where the tool is along the path.

What are the Different Types of CNC Machines, and How Do They Work?

There are many different types of CNC machines. We will now look at each type to help you figure out which machine is suitable for your project(s). The first group we will go over is electric discharge machines (EDM), including sinker EDM and wire EDM.

Electric Discharge Machines

Sinker EDM and wire EDM use electric current to remove material from an object.

In Sinker EDM, an electrical current is sent through a dielectric fluid that contains tiny metal particles. The sparks cut away at the workpiece within a few thousandths.

Wire EDM is a process that uses a thin wire to remove material from your part. It is very accurate and can produce intricate pieces of metal. The main difference between it and other methods is removing the material, but both processes are considered accurate and efficient.

Electric discharge machines are exact. You can get the results that you want without much waste. The disadvantage is that these machines are not easy to use, so they are not suitable for beginners.

CNC Mills

A CNC milling machine is a bit like a drill press, but the guide moves along multiple axes (typically X, Y, and Z) to carve shapes out of different pieces of material. The maximum thickness it can cut is 1-2 inches.

This type of bit can take such thicknesses because it works differently than milling machines or drill presses. It is less likely to cut away at hard materials like steel with a bit larger in diameter.

CNC mills can take more significant bits than other machines. This might not seem like a good thing at first, but if you need to mill out a lot of space on your part, it makes a big difference in which machine you choose. These machines can be great for drilling holes or creating pockets where parts can be inserted.

The downside is that they can be more difficult and expensive to use than other options, and you may need to experiment a bit to get the results you want.

Water Jet Cutters

Water jet cutters can quickly and easily remove rigid materials like metal and stone. They use high-pressure liquid, like oxygen and water, to do this. This makes the machine very precise. It also leaves parts looking smooth, with little or no grinding needed afterwards.

This type of cutting machinery is fast and accurate and leaves a smooth finish on different pieces. The downside is that these machines are typically more expensive than other options and may require some trial and error to get the results you want.

Plasma Cutters

Plasma cutters are very similar to water jet cutters in terms of what they can cut. The difference is how they do it: plasma cutters use a gas (like oxygen or nitrogen) to blow up a piece of metal. The metal is then split into two pieces because of the high temperature from the plasma arc. The molten metal and the plasma go everywhere.

Plasma cutters can cut through materials with accuracy, and very little work is needed afterwards. However, they are more expensive than other options and may require experimenting to get your desired results.

Lathes

Lathes are machines used to create cylindrical shapes out of different materials. They can also make tapered or flat shapes on parts with a narrow edge. Most lathes today are operated by a computer.

This means that you can put your part in, program it using software, and the machine will do the cutting for you. You don’t need someone there to help unless there is a problem with your program.

These machines are accurate and can cut through thick pieces of material quickly. They are also expensive, so you must be careful when using them.

Other Things a CNC Machine Can Do?

CNC mills and lathes can carve down materials and turn them into something different without going through another machine. This is because they have high levels of accuracy, some reaching up to one-thousandth of an inch.

This makes it possible to create things like rings, bracelets, or any jewellery that needs a tight diameter to keep the material from spilling out. It could be complicated if inner grooves and double helix spun spirals are carved.

Conclusion

CNC machines can be used for more than just cutting through metal. Other machines can do the same job, but CNC machines are very accurate. They can also cut through hard materials like steel. If you need something to be created and have a tight diameter, CNC mills and lathes can help you out.

The best way to get the most use and value from machines like CNC mills is by understanding how they work. You can make many things with machines like 3D printers and laser cutters, but they cost more.

Even though CNC mills/lathes can create complicated pieces, they can also create smaller items and parts. This makes them popular among hobbyists and makers. Examples that can be made on a CNC mill/lathe are model car kits, scale models, and fidget spinners.

POSTED BY

POSTED BY